It has been another successful and rewarding year for PSM, which saw us maintain our strong growth trajectory, invest in new equipment, expand our team, and strengthen our partnerships with local agents.

An additional 5% growth in business for 2024, as well as maintaining the 25% growth we saw in 2023, has allowed for significant capital investment in new equipment. We have invested in some of the latest state-of-the-art equipment, including an environmental chamber, precision pressure sources, a laser etching machine, and advanced digital measurement tools. These tools have enabled us to streamline and automate our production and calibration processes.

We welcomed three new employees to the PSM team to strengthen our capabilities in our Sales, Production, and Development departments. We also continue to invest in employee development through apprenticeship schemes, with members of the Production team successfully completing IPC610 training to enhance the quality inspection of all electronics to IPC Class 3.

We continue to strengthen our partnerships with partners and agents, through successful online training sessions and in-person visits.

Product Innovation and Market Leadership

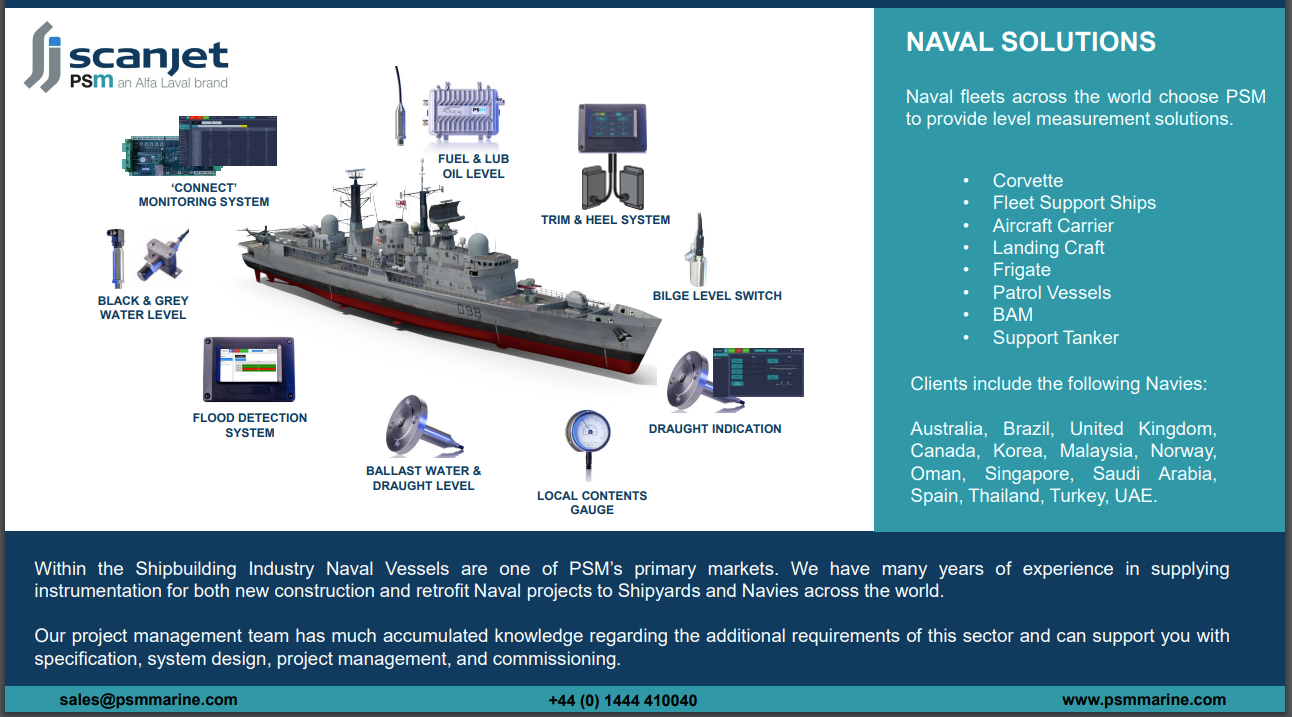

Our cost-effective APT1000 and VPM digital systems have become the industry standard, and are the first choice for many applications, including Tugs, Mega Yachts, Ferries, Naval Vessels, and Tankers.

We have also introduced innovative product enhancements, such as purpose-designed monitoring systems for Vessel Draught, Trim, Heel, and Flood Detection.

A Bright Future

We are proud to have secured several major contracts for full tank gauging systems for military vessels, solidifying our position as a leading supplier of TLG solutions for Naval platforms.

We are already planning ahead for 2025, and we look forward to sharing some exciting new developments with you in the new year.

We would like to take this opportunity to wish all our valued customers, suppliers and agents a very Happy Christmas and Best Wishes for 2025 from everyone at PSM.