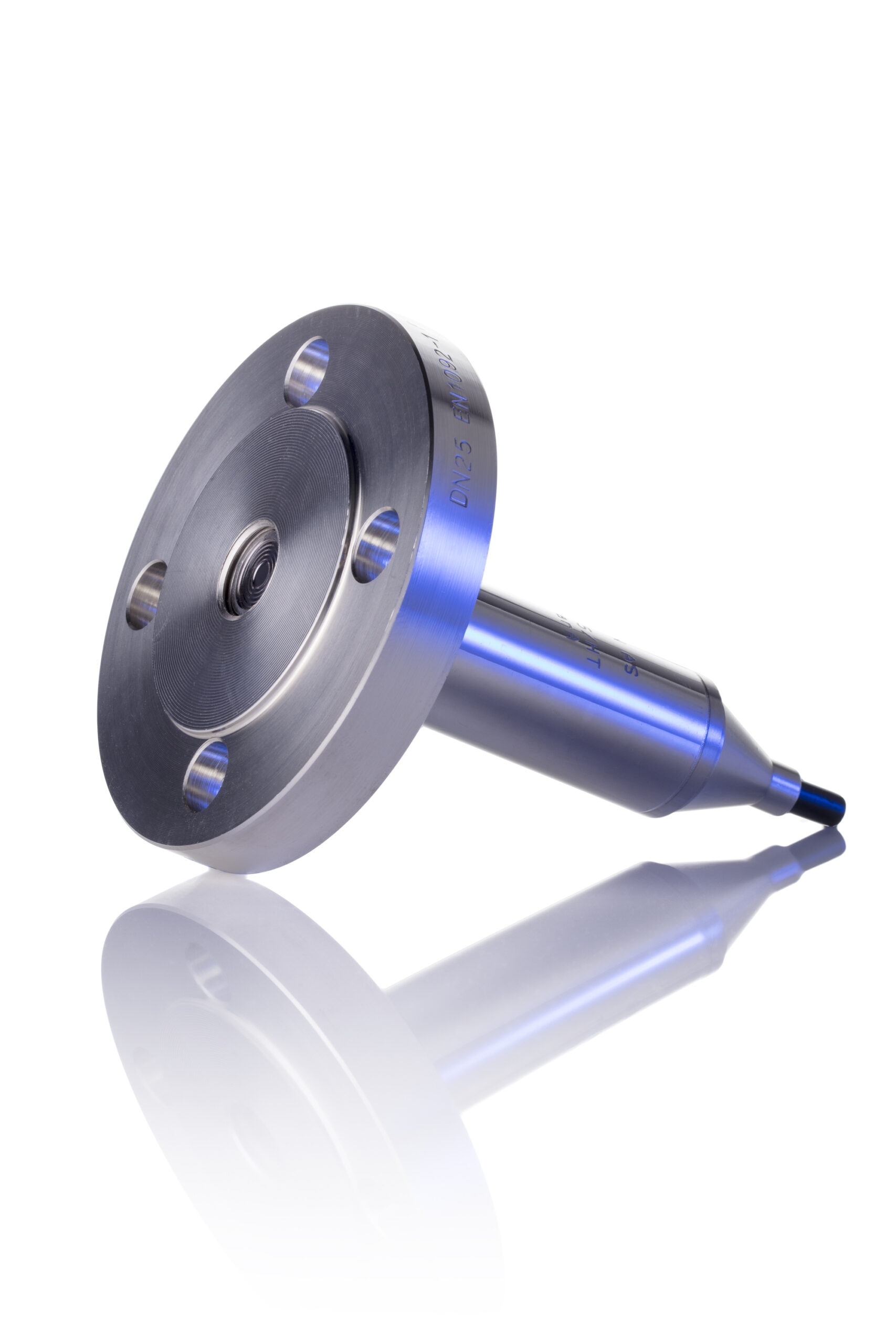

If you are considering the selection of hydrostatic transmitters for both newbuild and retrofit tank gauging installations, it is important to consider the overall installed costs. PSM’s APT1000 transmitters are competitively priced, but it is also their configurability and ability to communicate over a network that really brings down the total costs.

Because the transmitter is programmable, it is simple to set up and install by connecting to a laptop using software provided by PSM free of charge. Parameters such as sensor fitting height tank depth, liquid specific gravity, and even a tank look-up table can all be stored, meaning that the 4-20mA output can be set over any range and to represent tank level or tank volume.

This flexibility also simplifies in-service support. Should your parameters change, for example, liquid with a different S.G. is to be used, or a transmitter is damaged and needs replacing, changes can easily be made onboard by the ship’s crew.

When used in its second operation mode, as a digital transmitter, real cost savings are even more apparent. A single cable point to point network connects all APT1000’s back to the display system, which typically saves fifty percent of the cable required for a conventional analogue system, where each transmitter requires its own cable. Additionally, no analogue to digital conversion modules are needed, providing a saving on hardware.

In digital mode it is possible to connect to a specific transmitter to set it up from any point on the network, saving commissioning time.

Completing the picture, PSM’s RFM function modules provide termination enclosures for simple construction of the network, and a purpose designed safety barrier offers protection for an entire network in a hazardous area. This single safety barrier replaces the need for an individual barrier to protect each transmitter, meaning further savings vs a conventional analogue system where a separate barrier is needed for each individual transmitter.